• Fully automated process.

• Introduced the country's first two 180-box/hour German dual-host molding lines, hot-charging short-process production of molten iron.

• Use the world's most advanced environmentally friendly process equipment.

• Build a green factory in full accordance with A-level environmental performance standards.

• Modern Weiya CNC Machines with a CPK (Process Capability Index) ≥ 1.33, ensuring high precision in production.

• Optimized Clamping System for the rear pulling chuck, providing higher precision in product shape and dimensional tolerances.

• Automated Production Line with robotic arms for loading and unloading materials, ensuring no missed sequences or collisions.

• Separated Rough and Fine Turning Lines for wheel hub processing, which allows for better internal stress release.

• 6 Rough Turning Units for wheel hubs, and 10 Fine Machining Lines, achieving a daily production capacity of 5000 pieces.

• 9 Machining Lines for Brake Drums, with a daily production capacity of 4500 pieces.

• 2 Machining Lines for Brake Discs, with a daily production capacity of 1000 pieces.

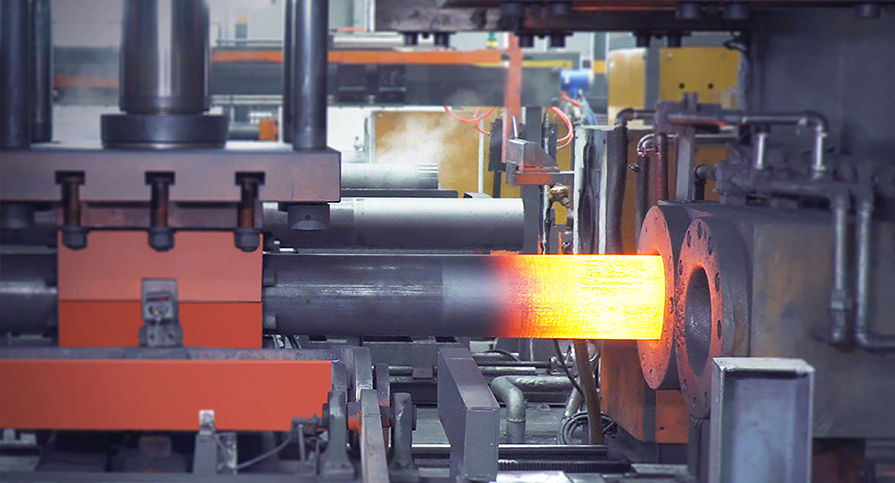

• Axle body forming manufacturing, with 6 world-leading seamless steel pipe integral extrusion forming lines with independent intellectual property rights

• Axle shaft (shell) body automatic intelligent production line.

• Make full use of the group company's steel pipe raw material advantages, high material utilization rate, short process, strong rigidity, long life,

• High precision, finite element analysis of axle body design, optimize wall thickness distribution, make the product lighter and have stronger load-bearing capacity.

• Machine tool intermediate drive, simultaneous shaft head processing, high efficiency and high precision.

• Automated production line, truss robot loading and unloading, stable detection unit.

• Automatic straightening, medium frequency quenching, Marposs online monitoring of grinding process.

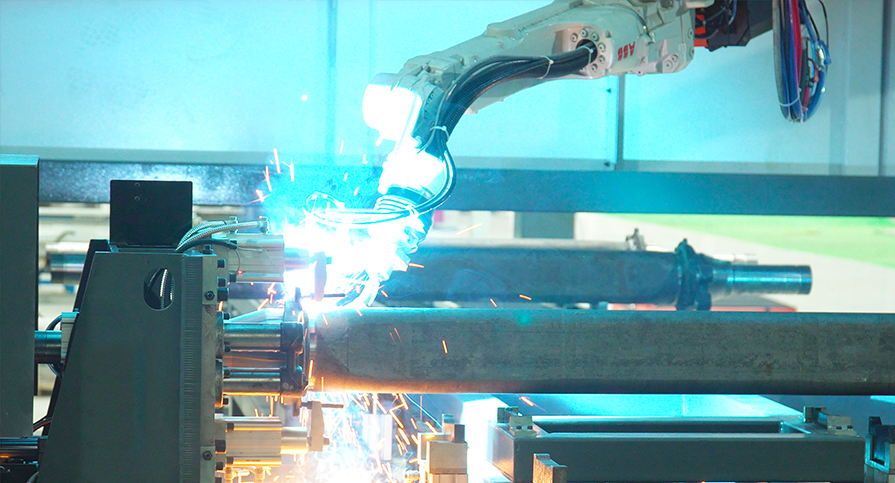

• Dual robot automatic welding. High welding precision and stable weld quality.

• 2 shaft machining and welding integrated lines, with a planned production capacity of 800 pieces/day.